Washing polluted soils for recycling and soil decontamination

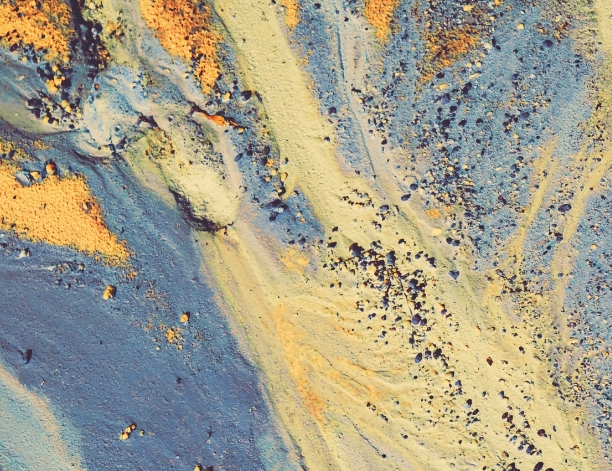

On former waste storage sites, the soil is often contaminated or polluted. Contaminants can be solid (concrete or metal remains) or fluid (chemicals, grease). Polluted soil treatment involves restoring the polluted soil to its natural state.

Solutions for cleaning polluted soil

The solutions used in polluted soil washing processes are as follows.

- The scrubber Roloflux® kneads the soil to release its components.

- Attrition cells clean the surface of the soil grains and release pollutants.

- The hydrocyclone removes suspended pollutants and creates particle size separations.

- The dewatering screen removes excess water from the soil.

Case studies

WITH YOU TO SUCCEED

NEYRTEC MINERAL can answer all your technical questions on the remediation of contaminated soil and recycling of construction materials.