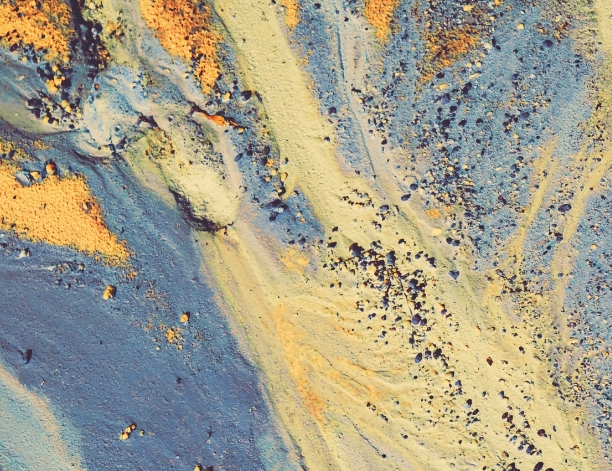

NEYRTEC MINERAL puts its 150 years of expertise at the service of its customers, mainly mining and quarrying companies. From a single equipment to a turnkey solution, our aim is to provide them with the right solution for processing materials extracted from mines and quarries. We enhance and optimize the treatment processes for the ores they produce. We adapt to the properties of materials, thanks to our wet treatment processes and solutions.

RECOVERY PROCESSES FOR MATERIALS ASSOCIATED WITH MINES AND QUARRIES

Focus on the core business activities of NEYRTEC MINERAL, specialist in wet processing for mineral recovery.

>> Material preparation

This stage is used to clean extraction materials from mining operations(including the scrubber ROLOFLUX).

>> Hydraulic classification

It includes granulometric separation of the components. It is used in particular for sludge and pulp from mining operations.

>> Water clarification and sludge thickening

These 2 processes are carried out using thickenerclariflux and high-capacity thickener, flocculation cells and thepaste thickener Tasster®-M.

>> Flotation

This is the most common separation process used in mining. Mineral separation is based on differential surface properties.

>> Gravimetric separation

This phase is carried out by cutting the ore, traditionally using spirals. Minerals are separated according to their different densities.

> > Fluid agitation and ores crushing

These steps are essential in any mining or quarrying operations.

Materials covered by our wet mining processing and extraction equipment

NEYRTEC MINERAL works on the valorization of over a hundred materials. These include quarry materials such as aggregates, industrial sands and kaolin. Mining materials such as phosphate, iron ore and bauxite are also central to our processes. Gold and copper are also among the materials processed by our equipment.

Case studies

WITH YOU TO SUCCEED

We are at your service to ensure the success of your mining operations in complete safety. Your satisfaction is our priority. Contact us!